Nickel electroplating, is the process of applying a nickel

coating to the surface of another metallic substance by means

of electrolytic deposition. Nickel plating is typically used to

provide greater wear and corrosion resistance and to add

thickness to undersized parts. Nickel plating may also be used

for aesthetic purposes, as nickel's brightness can enhance the

appearance of an otherwise dull surface.

NICKEL ELECTROPLATING AS A BASE LAYER

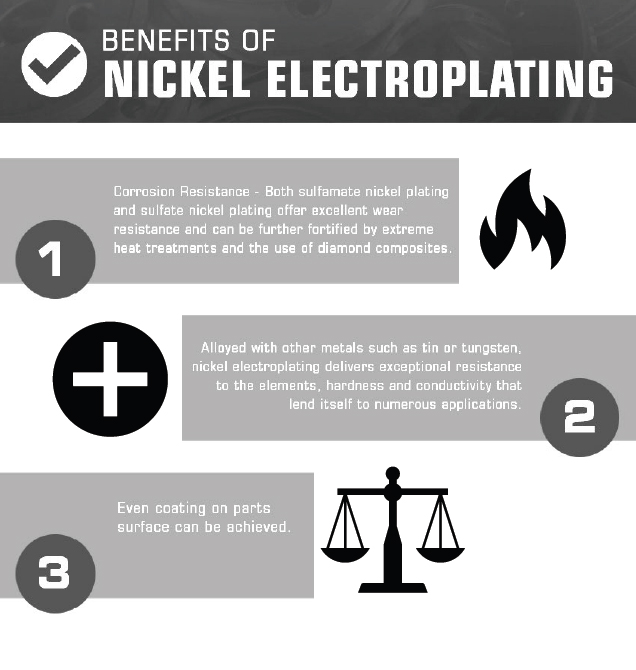

Both sulfate and sulfamate nickel plating can perform a variety of

important functions. One common function is to serve as a base

layer for secondary plating applications that is normally used when

coating precious metals such as gold and silver.

As indicated earlier, nickel electroplating also provides an effective

means of corrosion and wear resistance. Regarding corrosion

resistance, the highly micro-crystalline structure results in reduced

porosity and forms an extremely effective anti-corrosion barrier to

the basis material.

In terms of wear resistance, the hardness created by the plating

process can be enhanced through the use of heat, making the

resulting product similar to chromium deposits. When used with

diamond composites, materials such as silicon carbide, cubic and

hexagonal boron nitride, and tungsten carbide, nickel electroplating

can add intrinsic hardness by binding them into the plated surface.

This also serves to reduce static friction. Alloying nickel coatings

with metals or metalloids such as tungsten, tin, manganese and

boron which improves corrosion resistance, hardness, conductivity

and solderability.