The Beneficial Medical Characteristics of Gold

Gold features numerous characteristics that make it a viable alternative for medical use. Gold is biologically

benign, meaning it won’t cause a negative reaction when coming in contact with internal organs and other

areas of the human body. It is also unaffected by oxygen, moisture or ordinary acids, so it offers superior

resistance against corrosion of metal appliances placed inside the body. And despite its inherent hardness,

gold is an extremely malleable metal that can be easily shaped to develop high-precision medical instruments

and devices.

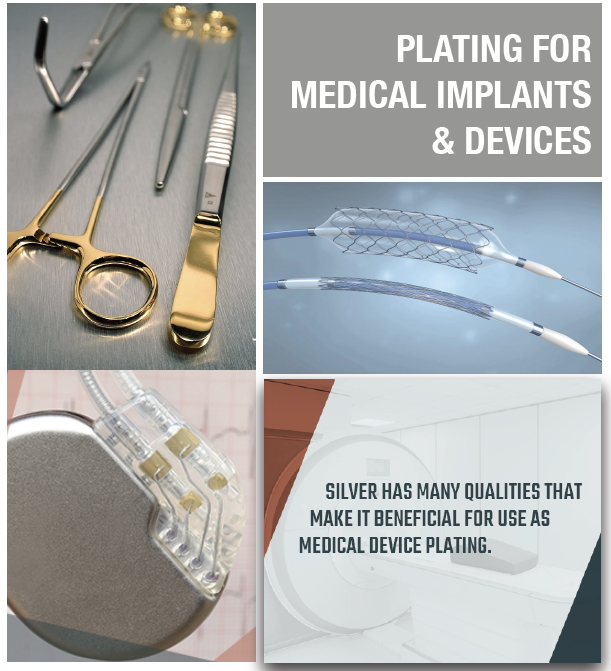

Typical gold plating applications in the medical field include:

- Production of electronic pacemakers to regulate a patient’s

heartbeat, as well gold-plated stents used to inflate and support

arteries

- Implants where minimizing the risk of infection is vital, such as

those used to aerate the inner ear’s tympanic cavity — thanks

to gold’s biocompatibility.

- Procedures by surgeons that clear clogged coronary arteries and

remove tumors

- Sealing of life-threatening injuries and wounds through emergency

physicians’ and battlefield medics’ use of lightweight lasers

that implement gold-plated contacts

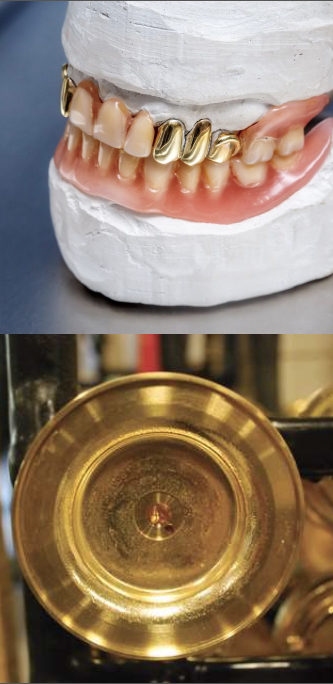

- Manufacturing of false teeth, caps and crowns in dentistry