PLATING SERVICES ON ALUMINIUM

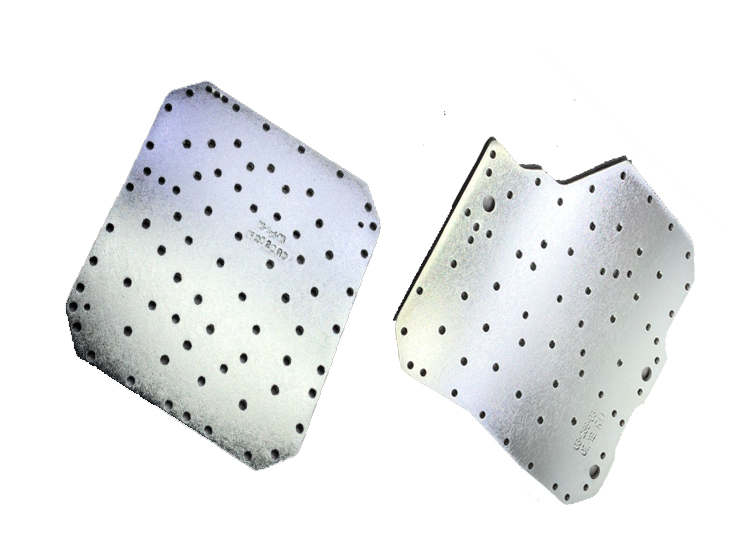

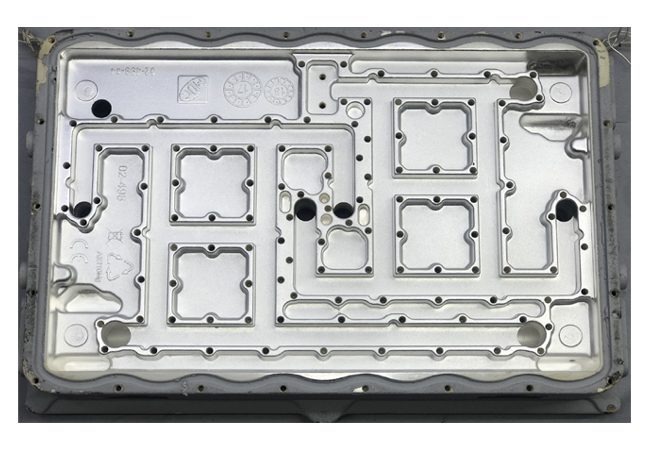

DIPLEXERS, FILTERS

& LIDS

Silver: The energy and power distribution industries rely in silver

electroplating of aluminum to improve corrosion protection and surface

conductivity. Silver also provides good lubricity and solderability.

Copper: Most of us know that copper is an excellent conductor of

electricity. Thus, copper electroplating is a preferred metal finishing

choice in the manufacturing of electronic circuit boards, semiconductors,

and other electronic parts and components. In addition to being highly

conductive, copper offers improved adhesion

Electroless nickel: An electroless nickel coating provides exceptional

corrosion resistance and will increase the lubricity, hardness and wear

resistance of the aluminum substrate. Electroless nickel can also serve as

an undercoating to strengthen and promote the adhesion of other plated

metals.

It's hard to imagine going through an entire day without

seeing, using or coming into contact with an object that is

made of aluminum. This soft, lightweight, durable metal can

be found in everything from aircraft and vehicle parts and

components to food and beverage containers, foil wrap,

windows and doors, lighting poles and much more.

With more than 25 years of metal finishing experience, you

can count on LEPL to provide superior aluminum

electroplating services that will exceed your quality and

performance expectations and meet your budget

requirements. We also have the expertise to help you select

the best aluminum alloy plating process for your

manufacturing projects.